Since the release of glass thickness gauges, it has never been easier to calculate the thickness of any glass and the size of the air-gap between double and triple glazing. Quick and easy to use, there is no special training required before using the gauge.

Using a laser gauge does the job of calculating glass thickness very easily. A few of the benefits include:

- No need to remove glass – measurement is completed in situ

- Fast & efficient – simply hold the gauge to the glass and the thickness appears on screen

- Accurate – no working out formulas or estimating required

How to Use a Glass Measurement Gauge

Readings can be taken from either side of the glass and glass never needs to be removed from its pane for measuring.

Use the glass measurement gauge on a single pane of glass as follows:

- Place the tool on the corner of a piece of glass

- Press the red button and hold down

- View the screen from a 45-degree angle

- Check the first laser line is on the zero line of the scale and the second laser line will show the glass thickness

- Once finished, return the gauge to its protective case ready to use on the next job.

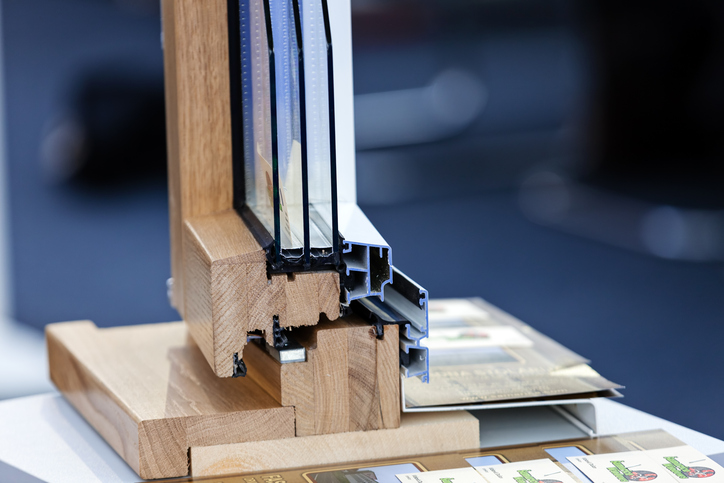

Different types of glass can be identified by the gauge. A single skin piece of glass will show two red laser lines while double glazed will have four red laser lines appear. If the double glazed glass is coated, one of the four laser lines will be brighter than the others. When triple glazed glass is detected, it will appear as six red laser lines.

Laminated safety glass is two panes with a polyvinyl interlayer between the panes. It appears as three red laser lines with one fainter than the others indicating the interlayer.

Use the glass measurement gauge for double glazed glass as follows:

- Place the tool in the corner of a piece of glass

- Press the red button and hold down

- View the screen from a 45-degree angle

- Check the first laser line is on the zero line of the scale and the second laser line shows the glass thickness of the first pane

- Slide the scale’s zero line to place on the second line and read the air-gap scale on the gauge

- Slide the scale’s zero line to place on the third line and measure the thickness of the second pane of glass

- Once finished, return the gauge to its protective case ready to use on the next job

Who Needs a Glass Measurement Gauge?

Any occupation that needs to check the quality of glass will benefit from keeping a gauge nearby including:

- Glass importers and manufacturers

- Building consultant and inspectors

- Window and door manufacturers

- Window installers

- Risk and insurance assessors

- Property managers

- Tinting companies for buildings and automotive

Why Merlin Lazer?

Merlin Lazer are leaders in the field of glass measurement and identification. They have their head office in the UK and use distributors around the world to sell their high-quality products.

Other Merlin Lazer Products

Merlin Lazer also manufacture the following glass measurement products:

Toughened Glass Indicator

Toughened Glass Stress Viewer

Low E-Glass Coating Detector

Glass Analysis Kit

If you have any queries about glass testing instruments, call GSR Laser Tools on (08) 9409 4058 or email sales@gsrlasertools.com.au